PROBLEM

Following are the figures for the number of defectives in 22 lots each containing 2000 rubber beds:

| 425 | 430 | 216 | 341 | 225 |

| 322 | 425 | 430 | 216 | 341 |

| 225 | 322 | 280 | 306 | 337 |

| 305 | 356 | 402 | 216 | 264 |

| 126 | 409 | |||

Draw the control chart for the fraction defective, Plot the points on it. Comment on the state of control of the process.

Theory-

Control Chart for fraction defective-

We know that,

When Standard given as P = P’

Then control limits are given by-

Lower control limit,

Upper control limit,

Central Line = P’

When Standard not Given-

First we estimate the value pf P as-

Lower Control Limit,

Upper Control Limit,

Where,

A is a function of n (sample size ) and can be obtained from fraction defective chart for different value of n.

And if LCL becomes -ve than we take it as 0. Because fraction defective can’t be -ve.

R Code-

#Command To Remove Previous Objects

rm(list=ls())

#Loading Some Library

library(readxl)

library(readr)

#Loading The Given Data set And checking The Characteristics

RubberBedData=read_excel("class work 10.xlsx")

View(RubberBedData)

mode(RubberBedData)

#Creating Somr Variable

No_of_Observation=length(RubberBedData[[1]])

SampSize=2000

Sample_No=c(1:No_of_Observation)

#Calculatinf Fraction Defective In Sample

No_Of_Defective=RubberBedData[[1]]

FractionDefective=RubberBedData[[1]]/SampSize

View(data.frame(No_Of_Defective,FractionDefective))

#Estimating Population Fraction Defective And Control Charts

PooledFracDefective=sum(FractionDefective)/No_of_Observation

lcl=PooledFracDefective-3*(PooledFracDefective*(1-PooledFracDefective)/SampSize)^(0.5)

if(lcl<0){lcl=0}

LCL=lcl

UCL=PooledFracDefective+3*(PooledFracDefective*(1-PooledFracDefective)/SampSize)^(0.5)

CENTRAL_LINE= PooledFracDefective

View(data.frame(LCL, CENTRAL_LINE, UCL))

#Plotting The Process Control Graph For Mean Of Given Data

plot(Sample_No,rep(CENTRAL_LINE,No_of_Observation),type="l",ylim=c(0.05,0.3),col="black",lwd=3,ylab="Sample Fraction Defective",main="Fraction Defective Chart Of Given Data")

lines(rep(UCL,No_of_Observation),type="l",col="red",lwd=3)

lines(rep(LCL,No_of_Observation),type="l",col="yellow",lwd=3)

lines(FractionDefective,type="b",col="green",lwd=3)

#Drawing The Legend

legend("topright",legend=c(expression(bold("Upper Line = UCL")),expression(bold("Middle Line = Central Line")),expression(bold("Lower Line = LCL"))),fill=c("red","black","yellow"))

Insights From The R Console-

Obtained Sample Fraction Defective-

View(data.frame(No_Of_Defective,FractionDefective))

| S.No. | No_Of_Defective | FractionDefective |

| 1 | 425 | 0.2125 |

| 2 | 430 | 0.2150 |

| 3 | 216 | 0.1080 |

| 4 | 341 | 0.1705 |

| 5 | 225 | 0.1125 |

| 6 | 322 | 0.1610 |

| 7 | 425 | 0.2125 |

| 8 | 430 | 0.2150 |

| 9 | 216 | 0.1080 |

| 10 | 341 | 0.1705 |

| 11 | 225 | 0.1125 |

| 12 | 322 | 0.1610 |

| 13 | 280 | 0.1400 |

| 14 | 306 | 0.1530 |

| 15 | 337 | 0.1685 |

| 16 | 305 | 0.1525 |

| 17 | 356 | 0.1780 |

| 18 | 402 | 0.2010 |

| 19 | 216 | 0.1080 |

| 20 | 264 | 0.1320 |

| 21 | 126 | 0.0630 |

| 22 | 409 | 0.2045 |

Obtained LCL, Central Line And UCL-

View(data.frame(LCL, CENTRAL_LINE, UCL))

| S.No. | LCL | CENTRAL_LINE | UCL |

| 1 | 0.1328297 | 0.15725 | 0.1816703 |

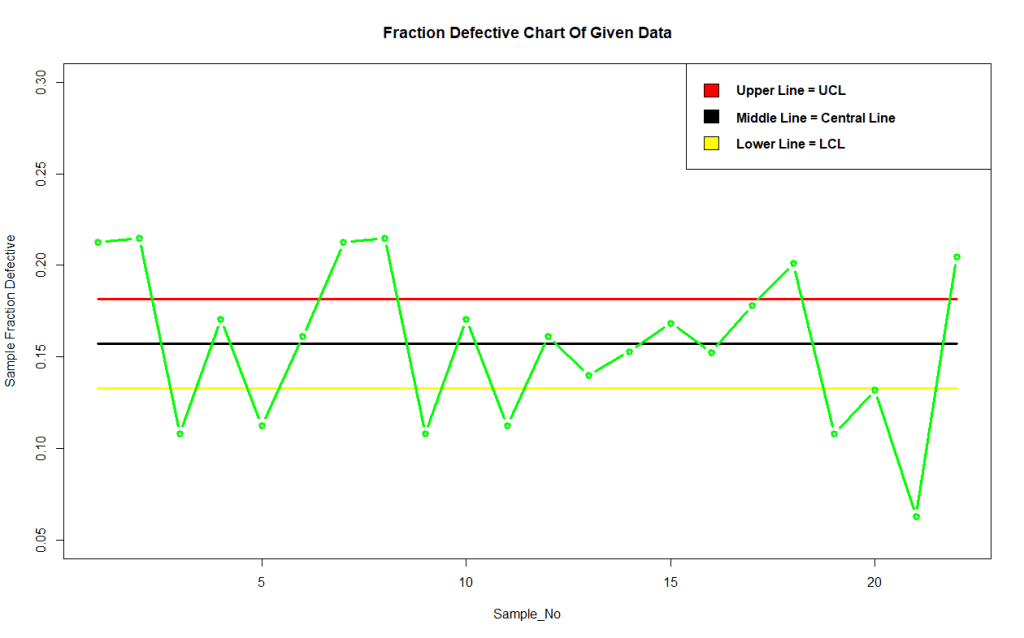

Obtained Fraction Defective Control Chart-

#Plotting The Process Control Graph For Mean Of Given Data

plot(Sample_No,rep(CENTRAL_LINE,No_of_Observation),type="l",ylim=c(0.05,0.3),col="black",lwd=3,ylab="Sample Fraction Defective",main="Fraction Defective Chart Of Given Data")

lines(rep(UCL,No_of_Observation),type="l",col="red",lwd=3)

lines(rep(LCL,No_of_Observation),type="l",col="yellow",lwd=3)

lines(FractionDefective,type="b",col="green",lwd=3)

#Drawing The Legend

legend("topright",legend=c(expression(bold("Upper Line = UCL")),expression(bold("Middle Line = Central Line")),expression(bold("Lower Line = LCL"))),fill=c("red","black","yellow"))

Conclusion-

In the above chart, we observe that many points are lying outside the control limits. Hence we conclude that the process is completely out of control.

Want To See Practically?

- download problem dataset.

- Copy-paste the R Code on RStudio.

- Goto, RStudio > Session > Set Working Directory > Choose Working Directory > “Open the folder where you downloaded the Problem dataset”

- Select The R Code > Run…That’s it 🙂